A Clear Path Forward for Transparent Bricks

/Have you noticed a change in clear LEGO bricks recently? More and more LEGO fans have commented on perceived changes in the clear materials used for certain parts, and they have called attention to it through forum posts and social media conversations that I’ve seen. Most noticeably, the comments center around three changes compared to older transparent elements: a slight color shift, slight cloudiness, and easier scratching (in the case of the windshield for the Ecto-1, set 10274).

Far Right: Cellulose Acetate. Others: variations of PC (Image via Istokg on the Brickset Forum)

So let’s talk about this recent shift in transparent LEGO—from the perspective of plastics! This article is not meant to be a deep dive into the history of clear plastics used at The LEGO Group (TLG), though I will briefly touch upon that now.

The Clues for a New Clear

For context, TLG has been making clear parts (also known as trans-clear) for a very long time with the earliest parts produced in the 1950s using Cellulose Acetate. The mid-1960s brought a shift to Polycarbonate (PC), which has stuck around for the long haul and is still used in many of the transparent parts today. There is good reason for its longevity! PC has superior clarity to many other clear plastics, high impact strength and durability.

However, its reign is likely coming to an end for an assortment of reasons (some of which are just speculations on my part such as when a PC part breaks it can be very sharp). You can almost hear the differences in materials. The older PC bricks sound sharper and have a higher pitch when dropped on a hard surface. Newer clear elements seem somehow softer and sound duller—but more like your typical colored bricks.

While safety is of course a possible driving factor, some light research turns up a post on the Brickset Forums where a fan mentions hearing directly from TLG’s Quality Director during the 2020 LEGO House Virtual Fan Day that the change is a result of a sustainability initiative. This conversation aligns with my personal experience in the plastics industry because PC is heavily scrutinized right now—and all but banned in Europe due to its use of Bisphenol A (BPA) as a monomer during production. It is certainly possible to formulate PC without the use of BPA but it does change the material’s properties.

Where Does This Lead Us?

I suspect TLG is now using a new clear material for some (but not all) of their transparent parts called MABS—short for methyl methacrylate-acrylonitrile-butadiene-styrene (phew!). In short, it is a completely clear type of ABS, whereas standard ABS is naturally an opaque milky white that can be dyed different colors. At first, it might be easy to gloss over that detailed point until you take some other factors into consideration.

(Image via Arne Hückelheim, Creative Commons)

In the past, if a clear part were to be made in Polycarbonate, it meant that LEGO would have to create a new injection mold specifically for the PC version (even if the part already existed in an opaque color). When the hot liquid plastic cools in the mold, it shrinks in size—and PC shrinks up to twice the amount as ABS!

Injection mold tooling is an expensive investment, and creating molds specifically for clear elements starts getting pricey. Presumably, the amount of new transparent elements TLG might introduce in a year was predicated (and limited) by their injection mold tooling budget. In other words, it was probably very limited.

Molds for MABS

So what did the recent shift to MABS enable? Quite simply, using MABS for the transparent material allows TLG to use existing part molds instead of creating new ones just for clear elements! (I’m sure with some limitations). The first proof of this shift came with the arrival of January 1st, 2022 sets. Can you spot it?

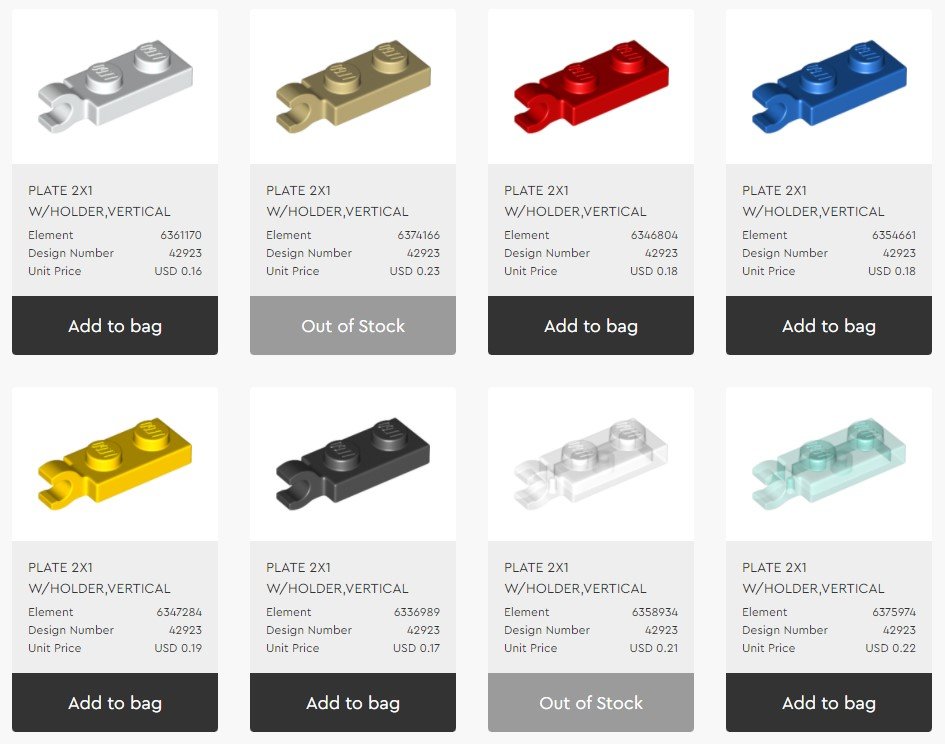

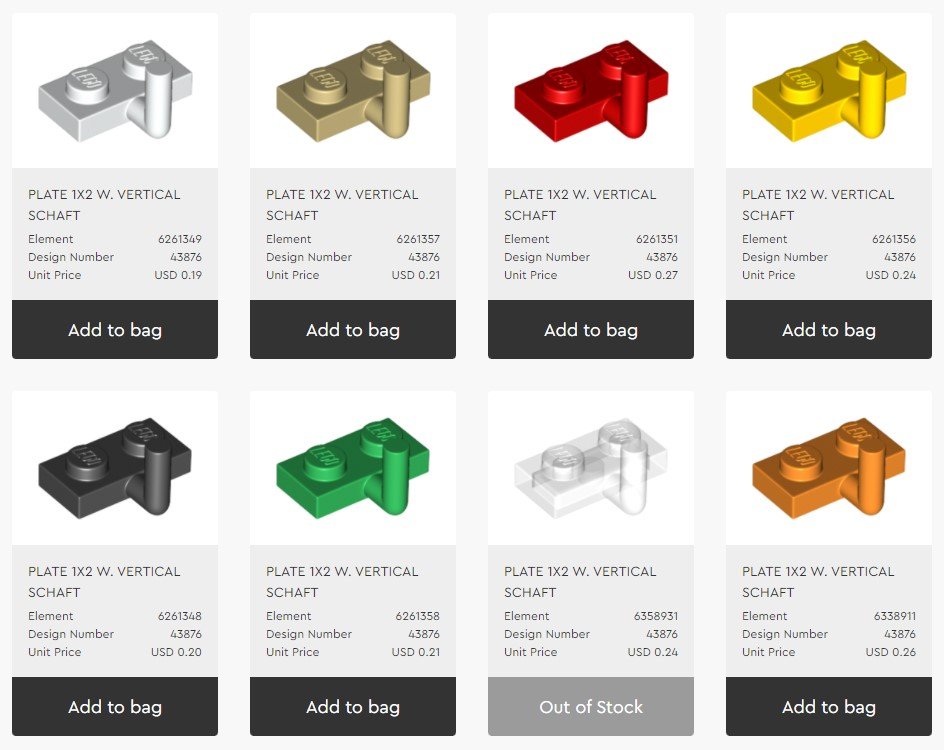

The part above (modified plate 2x1 w/ holder 42923) was introduced in both trans-clear and trans-light blue—but different from the past, the clear parts are now listed on Bricks and Pieces under the same design number rather than a different one, confirming they use the same existing mold as the opaque versions. (The same goes for 43876 plate 1x2 w/ vertical bar.)

I think it is safe to say many LEGO fans, including myself, could have never predicted getting a clip in transparent materials! This is all possible (and only possible) with the use of MABS instead of PC. Also, a clip made of PC would surely snap when used without adding extra thickness to the current part. PC is not great for crack resistance. This change means that designers have more budgetary freedom and flexibility to introduce clear recoloring in their sets without the need for an additional expensive mold.

Figures and Functions

Even more amazing in my view is the introduction of multiple minifig legs produced in a trans-light blue in Vidiyo Candy Castle Stage, set 43111. Though this is not the first time that has happened, it is the first time a pair of clear legs with no printing has appeared on a single minifigure.

(Image via LEGO.com)

Another clue is that the bear’s head has an opaque medium azure core which is then over-molded with trans-light blue. More than likely, that clear material is MABS since it is rather challenging to over-mold PC onto a non-PC substance from an engineering perspective. (I don’t have confirmation, but it makes sense to me.)

The Golden Age of Transparency

So what will we see from LEGO in the future with these new clear capabilities? With my background being Industrial Design and within the world of plastics, this is THE question that gets me very excited to think about! The palette of transparent elements has been very much limited until now, and for good reason. But if the cost of new molds for transparent parts is being removed with the switch to MABS, this change can bring a whole new world of creativity.

Perhaps we will finally see a minifigure collector’s dream of a fully transparent minifig! Perhaps we will see more creative and bold uses of transparent bricks. Perhaps we will start to see more functional clear elements. Perhaps we’ll enter a golden age of transparency! The switch to MABS for clear elements can almost be treated like the introduction of a new color—and LEGO loves to flood new sets with new colors like what we’ve seen with the new neon/vibrant yellow this year.

It is certainly my hope that LEGO designers are thinking about this and capitalize on the opportunity to use more transparent elements. Who knows, perhaps they are reading this article and will be thinking about it a lot more!

Best of BrickNerd - Article originally published on January 21, 2022.

Have you noticed the recent change in clear LEGO? What would you like to see designers do with more clear pieces? Let us know in the comments below!

Do you want to help BrickNerd continue publishing articles like this one? Become a top patron like Marc & Liz Puleo, Paige Mueller, Rob Klingberg from Brickstuff, John & Joshua Hanlon from Beyond the Brick, Megan Lum, Andy Price, Lukas Kurth from StoneWars, Wayne Tyler, LeAnna Taylor, Monica Innis, Dan Church, Roxanne Baxter, and Steven Laughlin to show your support, get early access, exclusive swag and more.