Molds Over Time: How Part Updates Change Build Techniques

/When you head over to your preferred third-party LEGO parts reseller and start looking for pieces, you may be surprised at the variety of results for a simple element search. Why, one might wonder, do four different pieces appear when you look for a 4085 vertical clip plate? Why are there three nearly-identical results for a 1 x 6 x 2 arch? And you may be even more confused when you receive your order: there was only one type of headlight brick to buy, but some of the ones you received have a little slot in the base and some don’t. Why were these not differentiated when the clip plates were?

ABS-king The Right Questions*

*Yes, my very first article is going to start with a horrible pun.

Well, that last question can easily be settled, at least, and it’s a good starting point to answer the rest. As of the time of this writing, the headlight brick actually does have two separate catalog entries on the popular LEGO part marketplace BrickLink: 4070 and 4070a. However, the entry for part 4070a, the one with the slot in the base, is marked for deletion, and many sellers do not bother to distinguish the two anyway. Why? Well, in the site’s own words: “This entry has been marked for deletion because the presence or absence of a slot in this part has been determined to be of little or no consequence to most users.”

Ah, so there we have it! We, as fans and Nerds, tend to only care about part mold variations when they actually have a meaningful impact on how we can utilize the pieces. You see, LEGO has updated a number of their older parts, and entire families of parts, over the years. Sometimes this is to strengthen the part, other times it’s to add utility, and sometimes it’s to accommodate interactions with new pieces. As a result, there are certain specific building techniques that can only be executed with some variants of these pieces. And, contrary to what you might expect, some of these part updates actually remove formerly available opportunities for build techniques! Let’s go ahead and take a look at some (DEFINITELY not all) of these specific instances where an updated mold of a piece either introduced or precluded building techniques that you can use in your own MOCs.

I’m going to group these rather loosely, and my opinions for these groupings are based purely on the techniques that I have chosen to mention as being available or unavailable. This is not me saying that, for instance, panel elements are simply worse now—it’s just a framework for the context of this article!

Upgrades: Parts That Gained Functionality

This is the most obvious category to talk about because a lot of elements were specifically designed to gain functionality with their mold updates.

3794 Plate, Modified 1 x 2 with 1 Stud, Jumper

The 1 x 2 jumper plate began as essentially just a 1 x 2 plate with a single stud in the middle, allowing pieces to be placed at a ½ stud offset. Design-wise, it remains an extraordinarily valuable piece in the LEGO parts library! It was updated in 2004 to add a groove around the base for easier removal, like modern tiles have, but the most substantial update occurred just six years later. In 2010, the pin in the underside was replaced with a stud holder, allowing a solid stud to attach to the center of the bottom.

3 generations of 1 x 2 jumper plate, plus the 1 x 3 jumper plate which inherits the same stud holders as the most recent iteration.

The added groove adds texture when viewed from the side and allows for techniques like building a brick wall out of jumpers and 1 x 2 plates. The stud holder added to the center allows the plate to be centered on any brick, not just open or hollow studs.

The texture of the brick wall or stack of money would not be possible with the oldest, non-grooved variant of this piece. The stud holder on the most recent variant allows this windowsill to be centered directly on top of a masonry brick.

6019, 4085, 2555, and more: elements with clips

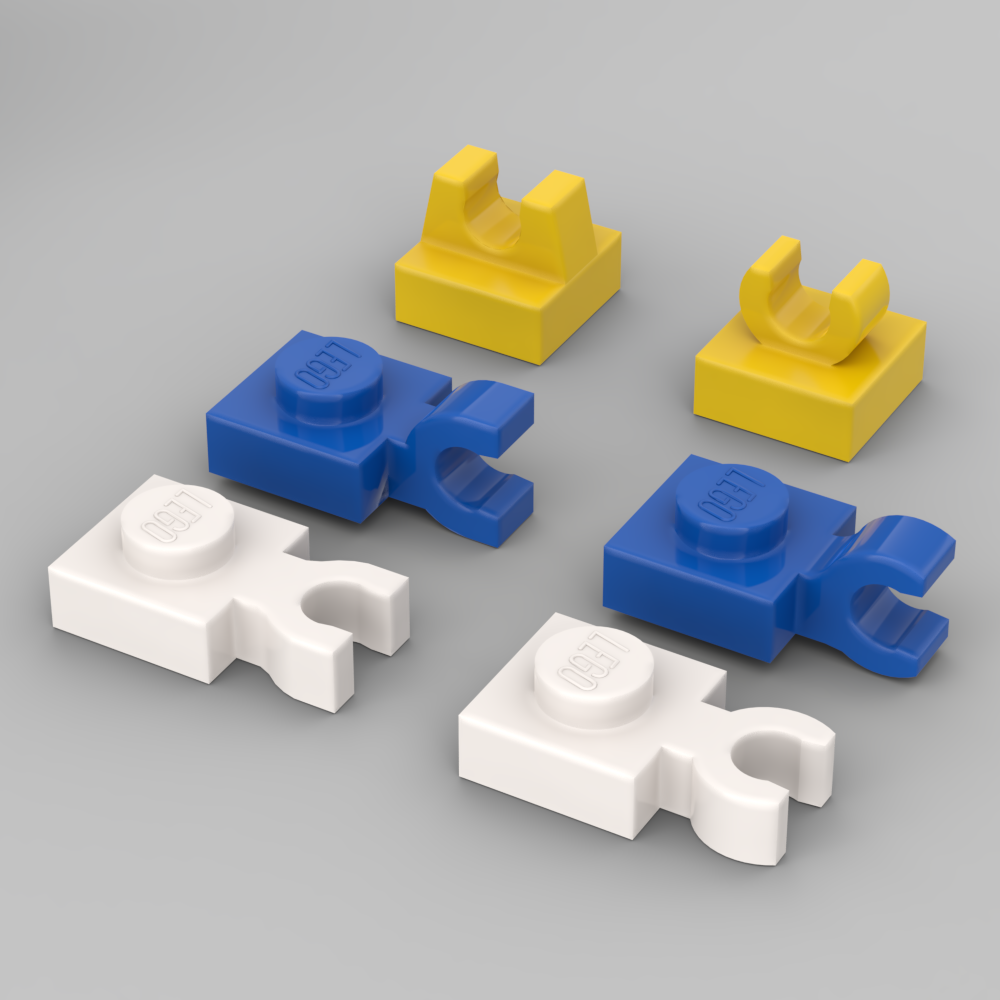

In the 2010s, the “clip” family of elements was revised to change the shape of the clips themselves from a U shape to a more rounded C shape.

The newest clips have a rounded C shape, with a continuous curve inside and out.

The main advantage of this change was that it allowed a technique that has been utilized by MOC builders for ages—using a clip to hold onto the side of a tile—to no longer stress and fracture the clip over time (a technique previously considered to be “illegal”.)

The flat silver 1 x 1 tile used as the side mirror is absolutely stressing that first generation orange clip tile right now. Believe me, I’ve fractured several this way over the years.

3455: Arch 1 x 6

Two wonderful Nerds, Dave S. and Are H., reminded me about 1 x 6 x 1 arches, which have been updated with a short, straight segment at their base before the actual arch begins, allowing pieces with the same curvature as a 1 x 2 curved slope to neatly nestle underneath them. The older version of the arch, whose entire interior space was arched, would not allow this fitment.

The older arch (above) has a radius that does match the 1 x 2 curved slopes, and there is no room for their ½ plate-thick bases, either. The newer arch (below) accommodates them just fine!

Downgrades: Parts That Lost (Some) Functionality

Again, this is not a condemnation: these parts are not bad, and they are not placed here to shame them. This category is a positive thing because it will highlight techniques available to you with older variations of these parts that you may not have known about!

4085 Plate, Modified 1 x 1 with Clip (Vertical Grip)

Although I put clip elements in the “upgrades” category, at least one piece in the family actually lost a bit of functionality in their transition to the newest shape of clip: the 1 x 1 vertical clip plate. Its third variant, with the thick U clip, provided the perfect amount of negative space in between two adjacent clips to hold a bar element with friction. Other versions of the plate can still hold a bar in this space, but not as firmly and perfectly as the U-shaped variant.

The third, or “C” version of the vertical clip plate, shown in gray, allows this weapon rack to comfortably hold 7 spears instead of 4!

This “trussed tower” I built also uses this technique for the columns on the ground level.

The clips allow me to fit 20 bar elements here using just 12 clip plates.

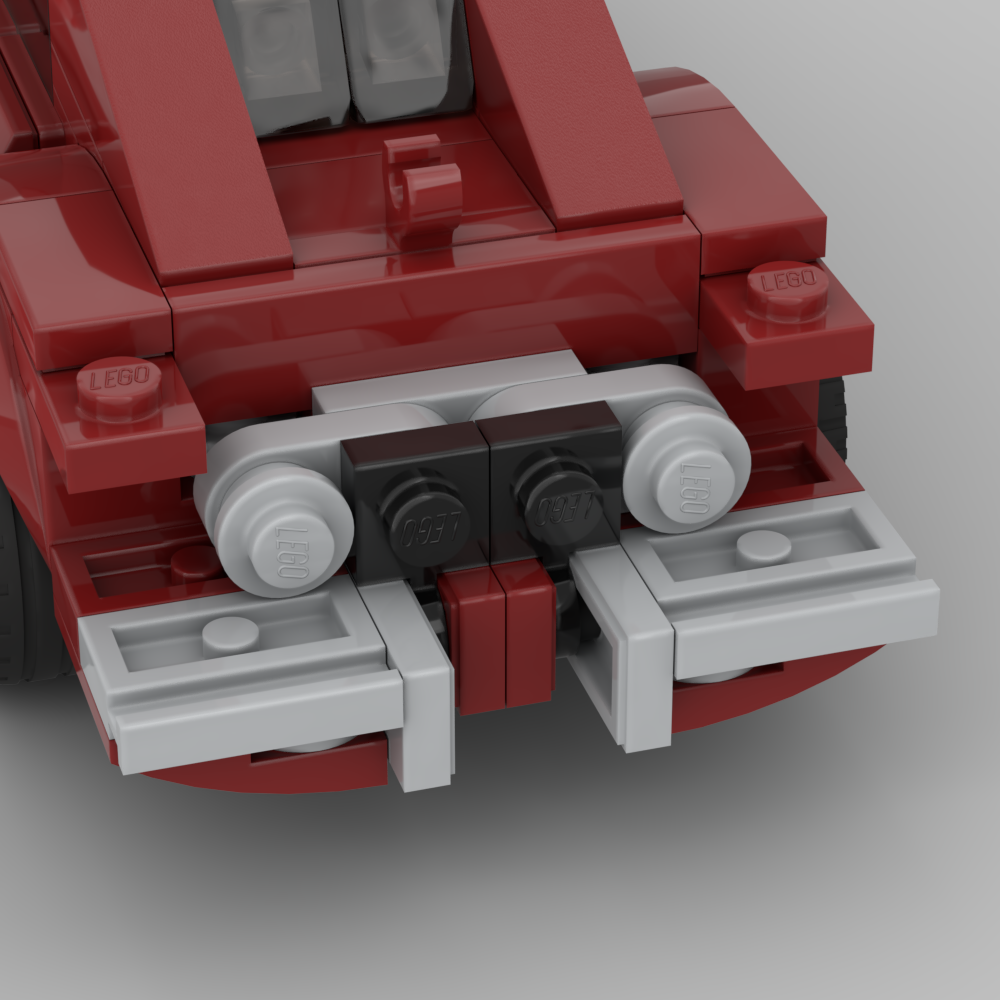

4864, 2362, 4215, and more: panel elements with studs on top

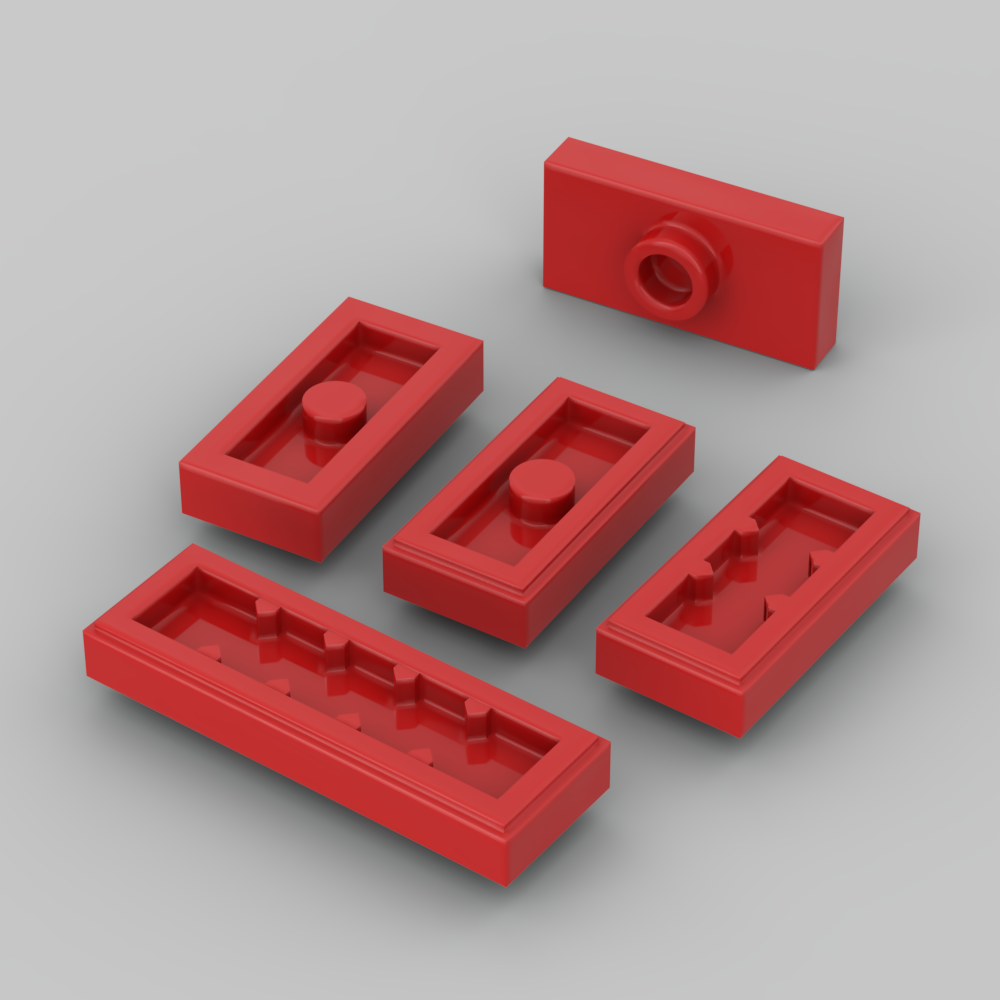

This next one also applies to a whole family of elements, those being most of the smaller panels with stud connections on top. I’ll be using the 1 x 2 x 3 version as a specific example. The oldest version of this type of part has solid studs and thin walls. The first update changed the solid studs to hollow ones, and the second update added reinforcing ridges to the edges of the panels to strengthen them.

3 generations of the 1 x 2 x 3 panel: solid studs, hollow studs, and hollow studs with side supports.

This one is very impactful to me personally, as I’m someone who builds cars and uses the 1 x 2 x 3 panel frequently as part of the chassis. I use them to drop the driver closer to the ground while still leaving clearance beneath the vehicle, much in the same way the dedicated vehicle bases work. The reinforcing ridges make the side profile of the piece twice as thick, removing any benefit of using a panel for this application.

This Dino 246 GT is a very small car, shorter than a minifig in overall height, but it still fits a driver thanks to the older 1 x 2 x 3 panel piece.

With the sides removed, the 1 x 2 x 3 panel is visible. Its thin wall allows for ½ plate of ground clearance while still fitting a driver (just barely).

3063: Brick, Round Corner 2 x 2 Macaroni

The 2 x 2 macaroni brick is one that lost some functionality when internal reinforcement walls were added. Previously, it was entirely hollow inside, which meant it could be overlapped when stacked, leading to very strong vertical structures. The current version cannot rotate as freely and must be reinforced some other way.

The older, hollow version of the piece (left) can be overlapped when stacked, while the newer one with internal support walls (right) cannot.

Additionally, the old one being completely hollow meant it could be cast in transparent PC and used effectively as a window, just like modified 1 x 2 bricks without central supports. The current version of the part has not yet been made in a transparent color, likely because the internal reinforcements limit its usefulness as a window.

This car’s windscreen uses a pair of older, hollow macaroni bricks in transparent clear.

Sidegrades: Parts That Changed In Functionality

This category is the most interesting to me because it will describe pieces that both gained AND lost specific technique functionality over time.

4081 Plate, Modified 1 x 1 with Light Attachment Ring

For the first several years of its production, this curious 1x1 piece had a thin ring that was ½ a plate thick (not including studs). The modern variant, in use since 1980, has a thicker ring that is a full plate thick, the extra mass added to make the part less fragile. This is a case where the update didn’t really add or remove anything, it’s just an alternative. Both have geometry that is uniquely useful and enables techniques that the other cannot achieve. That’s why it’s such a shame they aren’t both still equally available!

The newer part (on the right)’s ring is twice as thick as the original mold.

The tail light assembly of this 1970 Plymouth Road Runner utilizes the modern version of the plate.

The plate (blue) is centered and holds both halves of the tail light assembly. Its width exactly aligns with the centermost plate.

This C3, on the other hand, uses the older version.

Two of them are used side-by-side to hold the vertical 1 x 2 tiles of the rear bumpers.

4150: Tile, Round 2 x 2

The 2 x 2 round tile originally debuted with an interesting X shape on the underside, used as its stud holders. I actually cannot think of any other piece that had this design to it!

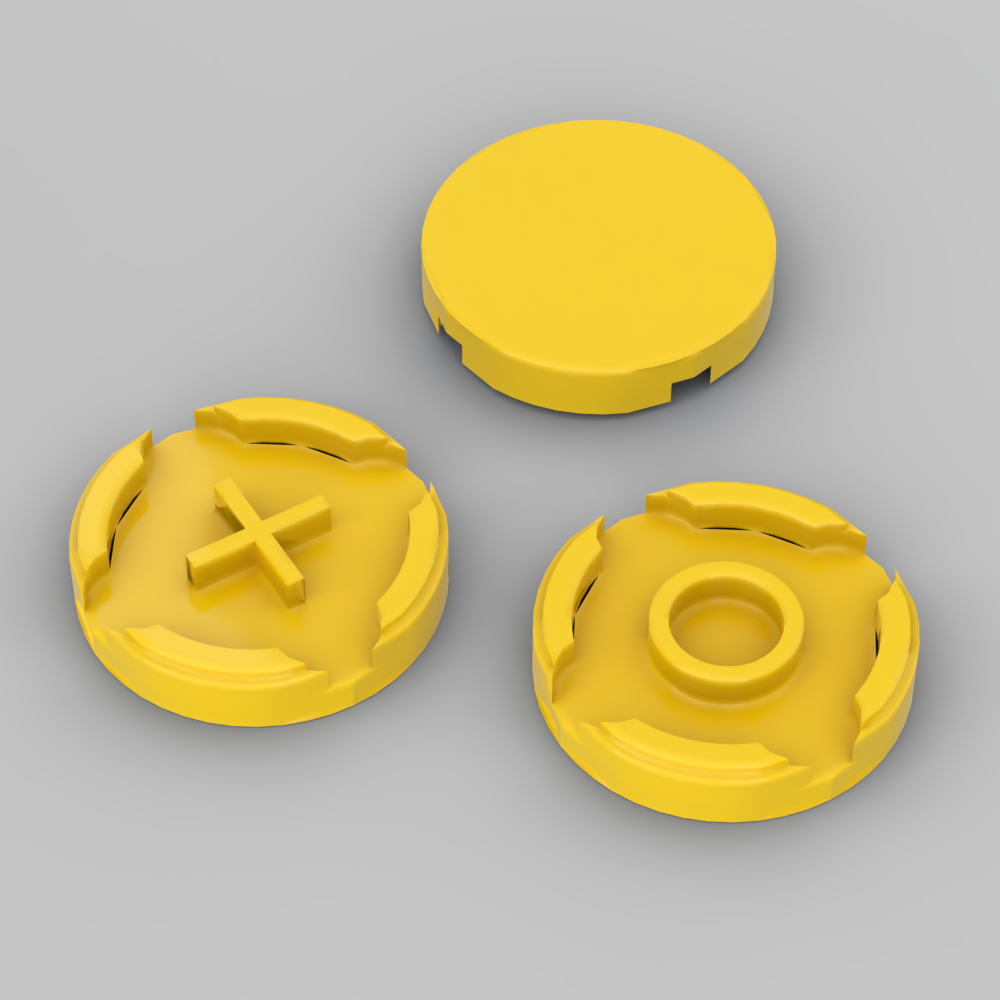

The unique X-shaped center of the old 2 x 2 round tile, compared to the stud holder that the modern version, and most other round pieces, have instead.

Due to the way studs are clutched by this shape, the older version actually has eight antistud connection points on its underside, with half of those being on a ½ plate offset from the standard, on-grid corner antistuds.

Red taps are attached to the on-grid (right) and off-grid (left) stud holders.

The sign for this record store features a smoke cloud made of 3 x 5 cloud plates and round tiles. The 2 x 2 round tiles used are the older version with the X underside.

This is why I used the older version: because it can be centered over 2 studs. The newer version, shown right, cannot - it will stick up or down from center.

3307: Arch 1 x 6 x 2

The 1 x 6 x 2 arch was updated in the 2010s after being used for over 40 years in its original form. The arch was made thinner and a support located on the underside was removed. It was updated once more shortly after with the introduction of the 1 x 4 x 1 ⅔ rounded top spoked window, thickening the arch to make the negative space underneath it exactly 1 ⅔ plates tall at its apex, so that the new window would comfortably seat in place without a gap.

The two older forms of the arch (left) do not cleanly accommodate the 1 x 4 x 1 ⅔ spoked window, providing either too much or too little space. The newest version (right) fits it perfectly.

Unfortunately, this version of the part also has thinner supporting walls along the arch, meaning that a previously viable trick of using the underside of the arch to grip studs, often used to decorate an archway with additional stonework, is no longer possible.

Cafe Corner, as well as countless Castle MOCs over the years, utilizes this trick. These 1 x 2 x 1 ⅓ curved slopes are attached to the underside of the 1 x 6 x 2 arch, which cannot be done with the newest version of said arch.

And Many More

Call that a starting point, folks. I hope some of these techniques are helpful to you because there is a world of amazing MOC-building tech locked away behind specific versions of pieces that are very much worth tracking down to experiment with. In fact, when I pitched this article, fellow BrickNerd Markus Rollbühler said, “Your element selection basically contains all ‘my secrets’ I always get asked about.”

There are tons and tons of pieces that have seen updates throughout the years, and many of those can certainly be impactful to the way you use them in your builds. I had to trim a lot of great suggestions out of this article to keep it from becoming a small book, so apologies if a noteworthy example didn’t get a shout-out, like the 2 x 2 x 2 cone or the large barrel half, but I’d love to hear all about y’all’s personal favorites!

Do you know of any other examples where an updated piece gained or lost functionality? Let us know in the comments below!

Do you want to help BrickNerd continue publishing articles like this one? Become a top patron like Charlie Stephens, Marc & Liz Puleo, Paige Mueller, Rob Klingberg from Brickstuff, John & Joshua Hanlon from Beyond the Brick, Megan Lum, Andy Price, John A. and Lukas Kurth from StoneWars to show your support, get early access, exclusive swag and more.