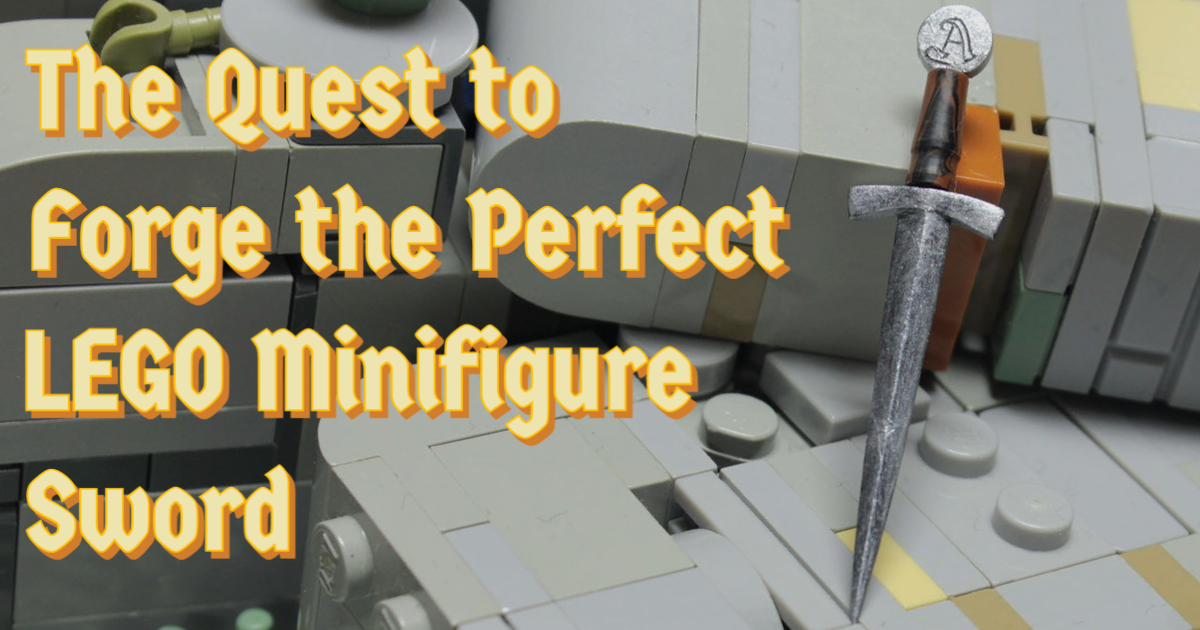

The Quest to Forge the Perfect LEGO Minifigure Sword

/For most LEGO fans, this sword might appear to be just another custom third-party injection-molded offering. However, for anyone involved in the minifigure modding world, this is immediately recognized as one of Detroitika’s many handcrafted masterpieces. Not a single aspect of the sword you see below was injected into a molded form. Instead, sections of the sword were shaped out of raw plastic using various methods and later assembled together into the final product. Cutting, lathing, sanding, drilling, gluing, painting and etching were all necessary processes in the creation of this exceptional piece.

So where did it all start? When I mentioned the usage of “raw plastic” I was referring to sprues. Sprues are the result of molten plastic left in injection channels which solidify after the injection-molding occurs. These sprues are attached to the product being produced but are not intended to be part of the finished item. They are excess plastic, removed after retrieving the desired object from the sprue. Because of this, they are typically regarded as worthless and get either discarded or recycled.

Detroitika, a.k.a. Tanner, utilizes this “worthless” material to its fullest and has incorporated it into countless mods beyond the swords we will discuss today.

On December 30th, 2016, four days after Tanner’s historic Sprue Sword post on Flickr, he revealed a complete breakdown of its creation as seen above. In it, he details every process used to create the finished sword we see today.

The process starts simply with him filing the sprue into the sharp shape of a sword blade. Next, he cuts a portion of the sprue off which he will use later for the pommel. Afterward, he files a section of the cylindrical sprue into flat surfaces that he can carve an outline of the crossguard. Using the outline as his guide, he files the now rectangular section of sprue into the required crossguard shape. Following that step, Tanner began to lathe a portion of brown sprue into a handle that can be gripped by a minifigure.

Nearing completion, we can see that Tanner drills out small holes to hold a tiny metal pin that can then be glued in and then attach each component of the sword together. Lastly, the pommel is carved and the sword gets painted.

Filing and lathe work of this caliber was unprecedented at the time of creation and remains relatively unrivaled. Tanner has created many more blades since and continues to expand on the fundamental concepts displayed in his first complete sprue sword.

On swords like Lazare in late 2017, he formed an intricate diamond-shaped pommel and carved a crisp fuller (long groove) in the blade. And in posts like Easy Does It or The Great Dane, he displayed fully functioning scabbards that compliment his boundary-breaking swords.

LAZare

Easy does it

The Great Dane - Oakeshott XVIIIe

I reached out to Tanner with some questions about his remarkable journey crafting custom LEGO minifigure swords. Here is our conversation as well as a few exclusive preview pictures of what he is working on next.

Billy: Hey Tanner! It’s a pleasure to have you join us on BrickNerd, and I really appreciate you being so willing to share insight into the process and creation of these pieces. On the Bricks & Banter podcast, you described how your father taught you how to use saws and files as you began customizing LEGO which equipped you with the necessary skills and vision to conceptualize and execute the creation of these swords. With that in mind, were there any prototypes or test swords using this process that predate your debut Albion Ringeck inspired sprue sword?

Tanner: Hi Billy, thankful to be part of this. I hope that some purist FOLs will read this and see how custom parts can work with, not against, their LEGO builds! I make swords to match real historical examples, and it makes LEGO scenes look that much more real.

Yes, there were several prototypes. The idea is like carving a statue out of a block of marble or a Pinewood Derby car out of the starter block. Experiments have to start somewhere! The first is one was LEGO’s old dark gray short swords with a rounded end. I naively cut into it but discovered that the semi-soft type of plastic (like many Bionicle parts) is unsuitable. Years later, taken an interest in the 1415 Battle of Agincourt, I cut and filed an entire sword blade out of a gift card. The material proved inadequate, but I began learning how to sharpen a block into a blade with my files.

Unpainted left/Painted With b carving right

Billy: Something unique to your debut sword is its engraved pommel. What did you do to carve such a precise and intricate letter A?

Tanner: The pommel is a round piece of black plastic the same diameter as a LEGO stud. Once it was painted silver, I took the tip of my hobby blade and cut shallow lines into the surface, revealing the black beneath. The other side has a fancy “B” making “BA” because I made the sword as a gift for BrickArms who created the plastic sprues.

The dremel lathe in action

Billy: An essential and stunning characteristic of these swords is their handcrafted handles. Did you have any experience operating a lathe before the creation of your swords?

Tanner: No I did not! That was a lucky coincidence. My grandfather used this tiny lathe to craft dollhouse furniture for his children (like individual chair spindles), and it was passed down to me. He handmade special lathe tools out of old, thick nails, and they remain the best tools for that lathe to this day. It was ideal to make the grip for Jon Snow’s sword from Game Of Thrones, “Longclaw.”

Billy: Have you used your Dremel lathe to create any other mods?

Tanner: Since trying sword handles, I’ve also made two medieval maces and one very special goblet out of an extra thick sprue.

Billy: In your posts displaying swords like The Great Dane or Damien blade with a custom handle, you feature fully functioning custom sheaths. What did you use to create these sheaths, and how were you able to hollow out the inside to accommodate the sword without damaging it?

Tanner: There were a few experiments with cloth scabbards. And more than a few failures. Sculpting clay for LEGO is an entirely different skill set, one that the LEGO part designers themselves have used since the last century. My method uses water to keep the sculpting putty (a brand called Pro-Create Putty) from sticking to the sword blade. I make a flat, pliable sheet of putty, wrap it around a wet sword blade, remove the blade, and let the putty harden. What remains is a working scabbard that just needs some trimming and painting!

Custom scabbards

Compound Hilt example

Billy: Thank you again for sharing your expertise with us at BrickNerd. Before you go, are you currently working on any new swords or have plans for some in the future?

Tanner: Hey, thanks for having me. I've got several in the works, especially ones to fit The Witcher universe. My next one is ambitious... so ambitious that I'm scared to keep working on it! It’s a sword from the 1500s when big broadswords were transitioning into rapiers, and it has a swirly, delicate extra set of guards above the crossguard known as a "compound hilt."

Gluing it in a sturdy way will be very difficult. When it is done, it will have a scabbard that fits between the floating guard and the blade. In the meantime, here are some sneak previews exclusive to this article. Thanks so much for having me! If people like Medieval customs, there are whole worlds of history to explore beyond LEGO’s limited and bulky accessories—shields, helmets, dresses and armor, jewelry and gauntlets, saddles and banners, and of course, *swords!*

Current works in progress

Best of BrickNerd - Article originally published February 23, 2021.

Have you ever modified any LEGO weapons? What do you think of these custom, hand-crafted minifigure swords? Leave your thoughts in the comments below.

Do you want to help BrickNerd continue publishing articles like this one? Become a top patron like Charlie Stephens, Marc & Liz Puleo, Paige Mueller, Rob Klingberg from Brickstuff, John & Joshua Hanlon from Beyond the Brick, Megan Lum, Andy Price, Lukas Kurth from StoneWars, Wayne Tyler, LeAnna Taylor, Monica Innis, Dan Church, and Roxanne Baxter to show your support, get early access, exclusive swag and more.